Filter By:

- 6607 views

Revisiting the concept of Fall Protection

A Fall Protection System is a solution to protect the user from falling or to…

Read More- 6483 views

Impact of knots on Rope strength

Ropes are popularly known as lifelines in the Rope Access industry as they save…

Read More- 6525 views

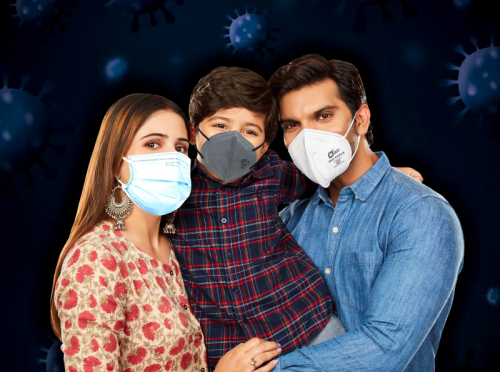

Selecting the right Mask for COVID Protection

Stopping the spread starts with taking the right steps. A lightweight, well-…

Read More- 6369 views

Selecting the Right Sole for Safety Shoe

Many workplace hazards can prove to be harmful to workers. An array of…

Read More- 6154 views

Why a Tripod and Winch are not enough for working in…

Globally approximately 2.1 million workers enter and work inside a confined…

Read More- 6066 views

All about ATEX Certified PPE

Explosive atmospheres can be caused by flammable gases, mists or vapours or…

Read More